Instructions

On this page you will find instructions for using products that I offer. The tutorials can be downloaded as a PDF file or viewed here on the website in individual sections. I believe that they will help you with building a beautiful model and historically correct models.

If you are interested in further advice or guidance on how to build models of historical sailing ships, I recommend that you search for literature. Rigging period ship models for beginners. Literature and plans of the highest quality can be found at ANCRE in France, or at the Historic Naval Ship Association - HNSA in the Manual and Documents section, where literature is in electronic form.

Manuals:

The procedure for installing a new ship stern:

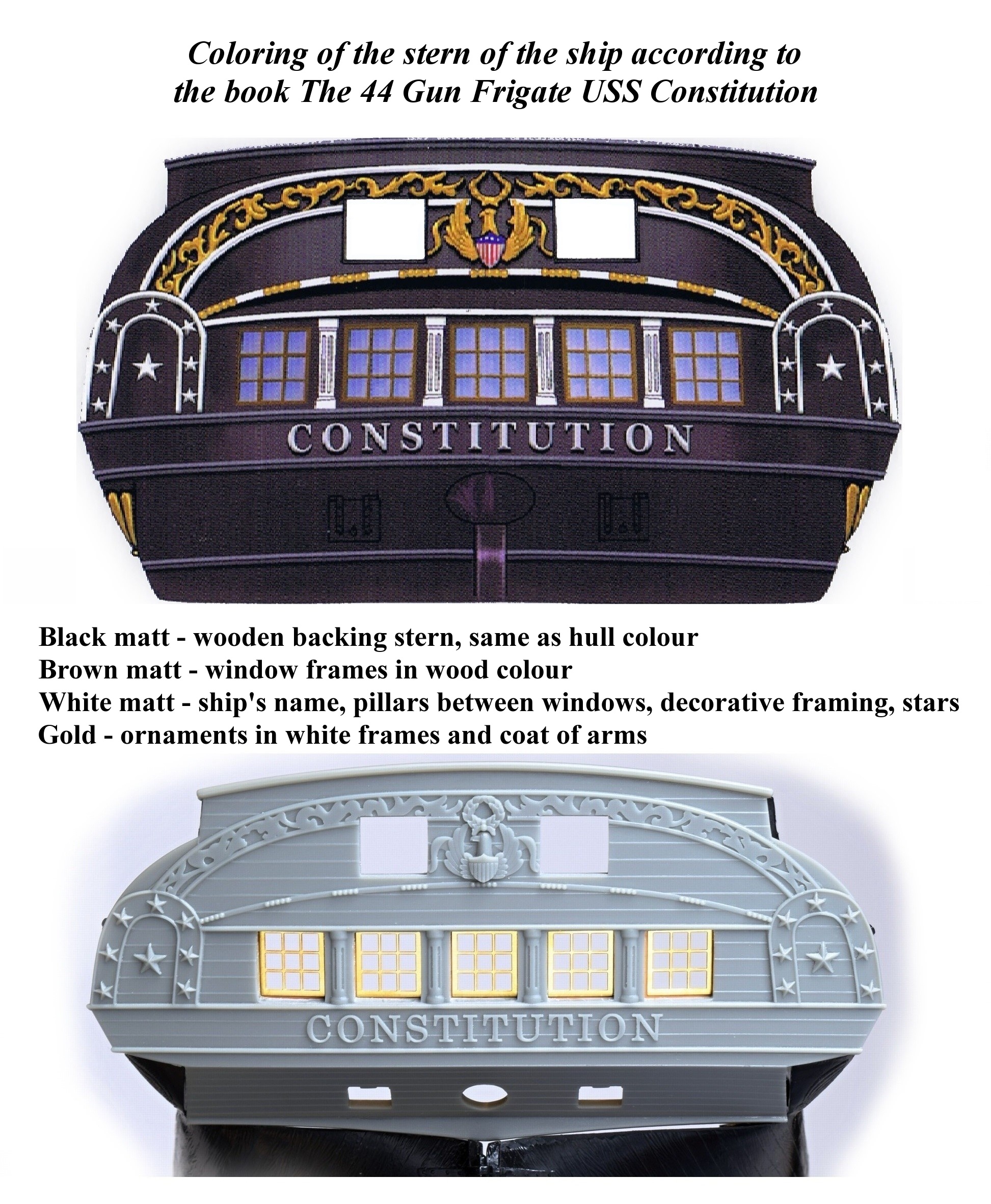

The new stern of ship was prepared based on the historical documents presented in the book The 44 - Gun Frigate USS Constitution by K. H. Marquardt.

The stern is supplied on a plastic cast from which the stern needs to be cut off. And then cut out the windows where there is only a very thin plastic membrane. After removing the molding from the cast, the plastic membrane from the windows, and any burrs from the stern molding, glue the windows that are photoetched. It is best to split the photo-etch window frame into individual windows so that they fit exactly into the prepared cut-outs. You can glue a regular transparent film to the back of the windows. Then you need to prepare and glue the bottom lids of the casings. Paint the stern of the boat according to the attached picture. Again, it is up to each modeler how they paint the details. Because there is no document on how the stern was painted. After painting the stern, you can glue it to the model in the same way as the original stern from the kit was glued. No modifications need to be made to the model in this regard.

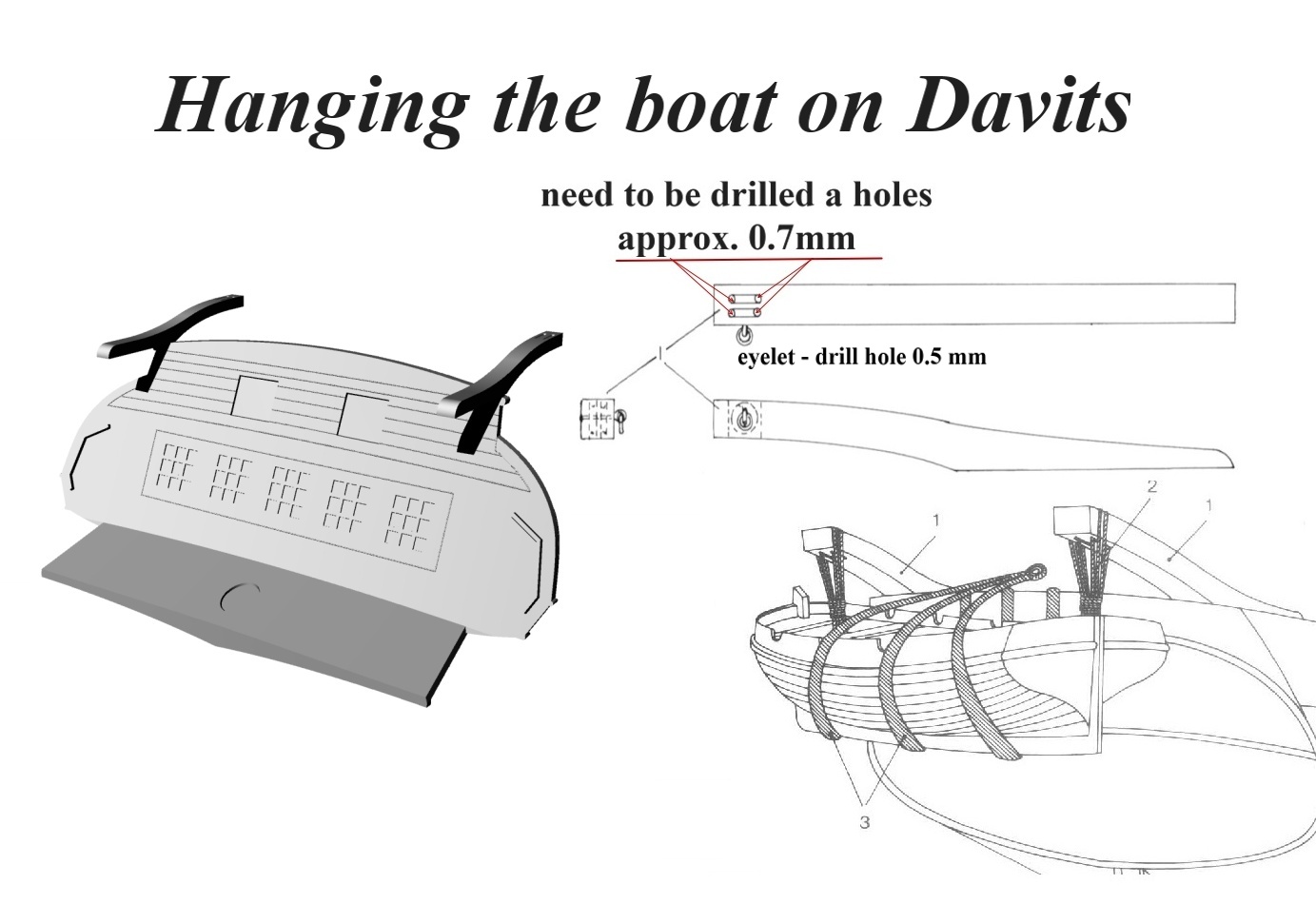

Davids:

Davids – these are the arms on which the lifeboat was suspended from the stern. First clean the Davids of manufacturing burrs and scrape all edges. Using the attached diagram, drill holes in the locations of the dents for the ropes of the davits to lift the boat, imitating pulleys. Use a 0,7 mm drill bit for this. Drill a hole of approx. 0,5 mm diameter in the assumed axis of the imitation pulleys on the inner side of the davits and glue a eyelet into it, into which the beginning of the rope for the lifeboat hoist will be tied. Paint the davits black, like the rest of the hull. Glue the prepared davids to the end of the sides of the boat.

And then we can hang the lifeboat from the kit. Again, we can use the attached drawing to attach and secure the lifeboat.

By installing a new stern, you will give your model a look that matches the historical background of the USS Constitution in the years around 1812. At the same time, the new stern fits much better structurally into the model than the original stern from the kit. The upper edges of the stern are aligned with the upper ramparts of the ship. This also gives the model the right look and feel, both structurally and logically.

Wishing you a beautiful model, and we look forward to having your photos.

Recommended steps for long guns

- firstly smooth out the surface of the plate on a fine sandpaper

- cut all parts from the plate by scalpel

- smooth out the edges of components on a fine sandpaper

- Drill the holes for the eyelets in the back part of gun carriages for the back hoist of gun. Use drill bit 0,5mm.

For the English type of guns carriage - one in the middle.

For the Continental type of guns carriage - two at the edges of the carriages

- glued the gun carriage together without of carriage wheels and the bottom of the wedge. I recommend a dispersive glue on the wood

- then painting by varnish or red paint

- gluing a eyelets, recommend eyelets diameter 1,5mm, my code PE-LO1,5/B

- slowly turn and depress the wheels to the axes of gun carriage. Attach the wheels to the axes by this side where the opening is expanded after the laser cutting

- adjust the height of the lower wedge below the center of the carriage so that the gun carriages is exactly seated on the deck. And gluing it. This way increases the area that is stuck to the mount ship board.

- then you can deploy the gun barrel

Recommended steps for Carronades

- firstly smooth out the surface of the plate on a fine sandpaper

- cut all parts from the plate by scalpel

- smooth out the edges of components on a fine sandpaper

- Drill the holes by drill bit 0,5mm for the eye of gun hoist and tenon of wheel.

- gluing the guns carriage together without of carriage wheels and the bottom of the wedge. I recommend a dispersive glue on the wood

- then painting by varnish or red paint

- gluing a eyelets, recommend eyelets diameter 1,5mm, my code PE-LO1,5/B

- Attaching wheels to the sides of the base of the guns carriage.

In the type of guns carriage A - using the nails, which must first be shortened to the required length

In the type of guns carriage B - only gluing in to base of guns carriage

- then you can deploy the gun barrel

First Clean ornament with an alcohol cleaner and spray it by gold paint. Pay attention to spray a very fine layer. Then paint relevant spots by blue color and by mat black color paint fine sticks, which holds a letters of name of ship.

Then cut ornament from a plate by scalpel. Try placing of these parts on relevant place on model. Unstick transfer foil from paper which you have in plastic bag. Put ornament on paper from transfer foil and spread gel superglue on the back of side of ornament. Then put ornament on sticky side of the transfer foil for easier manipulation. Finally with a help of transfer foil to glue ornament on its place.

Some information about CNC wooden blocks: blocks have on one side a small stalk after the final mill. These stalks are not possible to remove when blocks are finished during final sanded. The hand grinding of the stem of thousands of blocks is not in my power. I hope you will not mind. The stalk is easy to grind off by a few strokes before gluing a ropes.

The wooden blocks had usually darker color. Therefore, it is possible to stain them - the best way to do that is in alcoholic stain on wood. Put the wooden blocks into the stain and leave it in for 10 to 20 minutes. Then let it dry out on a smooth non-absorbent surface.

The rope for this use must be minimally as strong as the rope lead through the block. The rope is pasted by some adhesive material – „flexible superglue “. There is better way to use "flexible superglue „adhesive material, because the joint is flexible after getting dry, too. The block is convenient to be hold by fixed tweezers.

Then paste rope from the side, after getting dry from the other side. Coat with glue either sides of block or the rope during this procedure. It is necessary to take care of that rope must not stiffen outside the block, because of possibility to tie knots on it and even the block hangs on the boat naturally. Take care of pasting rope around midpoint of block. The rope pasting on a slant looks unsightly especially on big blocks. It is true, that you can´t hardly avoid unwanted visible staining surfaces by glue. Remove it by coating this place with some matt lacquer. I usually use fork made of needle for coating surfaces by glue. It is recommended to wet the rope slightly before using adhesive material because of better getting dry after the procedure.

Next procedure depends on size and width of the block. At blocks size 2 – 4 mm with 1 or 2 holes do knots just past the block.

If the block is wide enough, ropes surrounding the block are next to each other. In distance about 2 – 4 mm according to the width of block tie both ropes by thin thread together, paste the knot immediately and cut away one end. Wind the other end around the ropes in direction closely at the block for better fixation the joint.

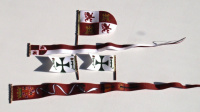

Flags are made by thermo-sublimation printing method on the synthetic cloth Whisper.

ATTANTION! – Flags must not be treated by acetone-based varnishes, paints or thinners and synthetics. Damage will occur – dissolution of color and destruction of the product.

Flags are printed in such way that their appearance and size ratio correspond to the historical facts, because there were regulations on the size of flags and banners given by all admiralties. Most of the time the size of the flags was in relate to the size of the ship, especially to its width.

Main flag in full size has a same long as width of ship. These the flags were use in official situation, battle and similar. Then was next main flag which have size 1/2 or 1/3 of Main flag. These flags were use in next common situation. Regulations determine when to use the flag of a given size.

Also, the size of the flags in the available sets is adapted to the size of the ship parts from the kit. This is especially true for the flagpoles at the top of the masts. There is an imitation of the “cloth strip” on the pole side of the flag, by which flags were attached to the pole or lifting rope.

Workflow for both-side printed flags:

Prior to use, iron the flags over a damp cloth or better through a low temperature food baking paper. Long-term exposure to high temperatures will damage the cloth itself and the flag print. All our flags are both-side printed.

To avoid fraying of the edges and to allow the flags to be shaped, I came up with a very simple method: Spray the flags with hairspray. Or spray or paint with acrylic lacquer. Or treat with diluted liquid laundry starch to soak the fabric.

After the flag has dried, we will cut it off. In case of banners and some flags, where printing of the lower side exceeds front side, we follow the front side.

After cutting out the flag, moisten it gently with water and shape it as it waves in the wind. To ensure the desired shape, secure the flag with objects to keep the desired shape until the fabric dries.

Procedure can be repeated until we are satisfied with result.

Then we fix the flags to the flag rope or pole.

I wish you nice results. Radek Beseda, HiSModel

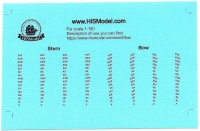

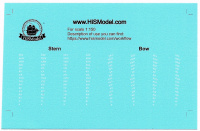

Draft scales on ships are used to quickly see how deep in the water the bottom of the ship is. Lightly loaded, the ship floats higher and heavily loaded deeper. For example, if the water surface is at mark XX, the bottom of the ship is 20 feet beneath the surface.

In the past centuries, Roman numerals have always been used for this purpose. The number and the gap have every time height one half of foot. In this way, was dive of ship detected exactly with a one half of the foot.

How to use a decal - Draft scales are made as a classic decal. This means that it is a thin membrane placed on paper with a special substrate. To move the decals to the desired location, it is necessary to immerse the decal in lukewarm water. You must wait a while. The decal firstly rolls up and then unrolls again. At that moment, a thin membrane of decals is ready to slide easily on the surface of the substrate. Carefully pull it down, for example, using the tip of a skewer and a dampened brush to the designated place that you have moistened beforehand. Be careful that the decal membrane does not shrink or even tear. For this reason, each scale is on the sheet twice. Then use the tip of a skewer and a damp brush on a damp surface to fit the decal to the desired location. Hold the decal with a tip of a skewer and use a damp brush to push bubbles out from under the decal. Finally, allow the decal to dry. The easy procedure on YouTube is HERE.

The HiSModel decal is universal to the 1/96 Cutty Sark and Thermopylae from Revell, the 1/100 HMS Victory from Heller, or any other ship of this period in 1/100 scale.

For Cutty Sark and Thermopylae, cut the decals so the bottom number is X and the top number is XXII. The waterline of the ship is between XX and XXI. See photo of the actual ship for reference as to correct placement of the decals.

HMS Victory is a bigger, heavier ship, so the decal should be cut with the bottom number X and the top number XXV. The waterline is at Bow in upper edge of XXII. And on a Stern is waterline in upper edge of XXIII. Again, see photos of the real ship for reference as to placement of the scales.

USS Constitution is a bigger, heavier ship, too. So, the decal should be cut in a Bow with the bottom number X and the top number XXIV. The waterline is at upper edge of XXI. On a Stern is need decal cut with the bottom number X and the top number XXV. The waterline is at below edge of XXIII.

CSS Alabama and USS Kearsarge from Revell at 1:96 scale are very similar in size. Here is the range of dive scales VIII to XVIII used, with the water line on the XVI digits, based on the boat plans in Andrew Bowcock's CSS Alabama.

We at HiSmodel wish you great success and a beautiful ship model!

Dear Modelers,

The table - calculation of rope diameter and block size HERE.

One of the basic elements of a good model of historic ships are blocks for rigging. It is relatively difficult to produce high quality blocks, especially in larger quantities. That is why our company HiSModel produce and offers high-quality blocks from walnut wood on CNC machine. We produce a wide range of blocks in sizes from 2 to 12 mm. Standard single, double and triple blocks are available in sizes from 2 to 10 mm. Moreover, we offer violin, ramshead and heart blocks in sizes from 4 to 12 mm. Deadeyes are from the production of Amati company. The dimensions and marking of blocks are in the table below together with photos. Photos especially of small blocks are magnified. We produce blocks, which correspond in shape and size to the British standard around the turn of the 18th and 19th centuries. We are also preparing to produce a second set of blocks that will match to the continental standards according to ANCRE.

You can find the offered blocks HERE.

For right choice of blocks, it is important to know which, where and what size of blocks should be used.

The best way to determine the right sizes of blocks is to use professionally prepared plans. If you do not have this option and you are unsure about the block sizes you need for your model, you can use an attached table. The table is based on information and tables from the book “Historic Ship models” by Wolfram zu Mondfeld, from pages 272 and 308. You can download the table with calculation of ropes diameters and blocks sizes HERE. In this Excel spreadsheet you just simply enter the required scale of the model and the actual diameter of the main mast on the main deck. All dimensions of ropes and blocks are calculated based on this table.

In order to make the use of blocks easy for you, I am preparing ready-made rigging plans for you according to the original documents. There are recommended blocks drawn according to clear symbols in these plans. You can find these ready-made plans for individual models together with other accessories on my website HERE. You will find all the sizes of the needed blocks in my plans. And based on the table above also corresponding diameters of ropes.

If you have further questions, write them on our e-mail below. I wish you beautiful models.

Warning - please note that the production of beech wood blocks is terminated. Therefore, I do not recommend you to buy these blocks for new projects. Rather, buy walnut blocks with much better quality.

Best regards, Radimir Beseda

Every passionate modeler wants his model to look as close to reality as possible. Wooden - veneer decks, which do not need to imitate the appearance of wood, can help to achieve this. In addition, the decks are marked in the veneer to match the boat construction practices of the time. The design of the perimeter planking is called "waterway". The laying of the individual planks and their termination in the waterway, especially at the bow by so-called "hooking" and tapering towards the bow and stern. Marking out the pins which were used to nail the deck to the timbers holding the deck, the so-called "treenline". The position of the planking corresponds exactly to the design of the ship.

By using our decks you will significantly increase the aesthetic appearance of your model and at the same time you will get closer to its real appearance (ship construction plans were used as templates for the decks).

Material:

The decks are manufactured by CNC laser burning on a custom made veneer strip. Only high quality, specially treated veneer is used, which is glued to the felt strip for added strength. The felt strip guarantees increased mechanical resistance of the product - high flexibility and resistance to cracking. At the same time, the dispersion felt surface makes it easier to glue the deck to the plastic parts of the model. The veneer is then sanded and polished to a total thickness of 0.3mm.

The veneer itself is selected to give a solid surface appearance, with minimal annual years pattern. Therefore, light oak, pear or beech is used as the material - the decks can be ordered in these shades.

The procedure of gluing a veneer deck:

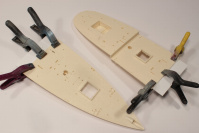

If you want to use a veneer deck, you must take this into account almost from the beginning of the construction of the model.

Note: Although the veneer is glued, it is relatively fragile, so handle with care! Take particular care to avoid cracking the narrow spaces in the deck between the deck openings, and damaging the deck perimeter when preparing to glue. And in the event that a crack does occur, tape the crack with fine paper - ideally tissue paper.

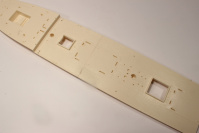

1) Preparation of the plastic base:

Some plastic decks have coils of rope on the surface in addition to the necessary protruding parts (such as hatches and other imitations). On the Glorieux and Superbe models by Heller there are recesses for cannonballs. All of this has to be removed with a scalpel or abrasive.

Check the clearance of the holes and apertures used to glue the other parts to the deck so that they are clear for the plastic part.

If the deck is multi-part, fit all parts so that they fit together exactly. If possible, glue the parts together and align the surface of the transitions between the parts (see Figures 2, 3, 4 and 5). I recommend gluing all corresponding plastic parts of decks together for example for USS Kearsarge, CSS Alabama, Cutty Sark and Thermopylae ...

2) Paint the deck to your preference - all the plastic parts of the deck that will be visible after the veneer deck is glued on. These are, boat grilles, deck vents and the such. (see Figure 6)

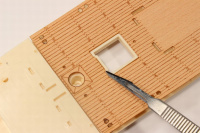

3) Cut the deck with a scalpel from the veneer strip - Cut on a firm, flat base so that the veneer does not warp during cutting! (see fig. 7) If small protrusions remain on the edge of the deck after cutting, they are removed immediately when the part is glued to the split plastic decks already built into the model.

4) Check that the veneer deck fits exactly on the plastic moulding.

If the plastic base is in one piece, the check is simple, and the veneer deck is glued to the plastic base before installation in the model. If the plastic deck is multi-piece, such as the Victory or USS Constitution lower decks, the veneer deck must be checked for "dry fit" in advance.

It may be that due to the expansion of both the plastic and the veneer, small differences will occur and the veneer cannot be accurately fitted to all deck tabs. In this case, sand the plastic part, especially the corner parts near the deck, with a file or adjust with a scalpel (see Fig. 8).

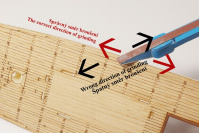

In case you need to adjust the internal holes, you can use a scalpel or a file. Measure exactly how much the veneer needs to be adjusted. Place the veneer on a firm backing suitable for cutting with a scalpel. Attach a guide rail to the cut area. Make the cut itself in a gradual notch, separating up to 3-4 strokes - this will prevent the scalpel from accidentally going off the axis of the cut. If you want to sand the holes with a file, use a fine flat file. Place the veneer on the edge of the table, with the sanded area as close to the edge as possible. From the top, press a firm pad again as close as possible to the sanding point. Then sand in longitudinal strokes, not directly perpendicular to the material.

If the veneer deck does not fit around the perimeter, we make the adjustment after gluing!

5) Spraying with varnish:

Spray the decks with a matte or semi-gloss varnish so that you don't get the deck dirty when you glue it and so that the overflowing glue doesn't stain.

Another possible finish is staining the veneer, which is done before spraying the varnish. For staining, use only an alcohol-based stain that evaporates quickly and prevents the veneer from warping or cracking. Apply the stain in small quantities, ideally using only a damp cloth or sponge.

6) Final preparation before gluing:

To prevent excess glue from leaking through the small holes in the veneer and making spots, seal them with duct tape. Prepare glue in sufficient quantity and means for spreading the glue over the surface of the plastic deck and wiping off the excess glue. Also prepare a roller or other means of applying the final pressure to the plastic substrate (see Figure 9).

Prepare a firm, flat gluing surface and a means to load the glued decks - ideally, clamp the glued layers between firm pads. If you are gluing on plastic decks that are already built into the model, it is advisable to use a bulk material of heavier weight in pliable bags for the load.

7) Gluing:

The most suitable adhesive for bonding veneer decks is a two-component epoxy adhesive. Plastic model glue can also be used, which has a high viscosity and can be spread easily. Suitable glues include Revell Contacta Liquid 39601 or TAMIYA Extra thin, among others regular Pattex or Titebond.

Dispersion adhesives are definitely not preferred as the plastic model deck is a non-absorbent material.

If you are gluing the decks outside the model, spread the glue in a thin layer over the plastic deck. Proceed quickly, using a brush and squeegee to spread. Spread the glue carefully, especially around the edges, internal holes and where other parts are to be glued to the deck. Apply the glue only in a very thin layer!

Once the veneer deck has been applied to the plastic substrate with the adhesive, press it down properly with a roller or other slippery material. Apply pressure by stroking the deck from the centre to the edges. Again, concentrate mainly on the areas around the edges, internal holes and where other components are to be glued to the deck. Wipe off excess glue as you go.

The glued layers can be weighted down on a flat surface or clamped with clamps and left to dry for at least 24 hours.

8) After the layers have dried - remove excess glue from the edges with a fine file (see fig. no. 10). Drill the glue-clogged holes again, drilling from the top as drilling from the bottom could chip the veneer.

9) Finishing:

For the final finish, use a coating or spray with a covering varnish. I recommend a semi-gloss varnish, which does not attract dust as much as a matt surface.

Have fun and the best possible result of your model.

Radek Beseda

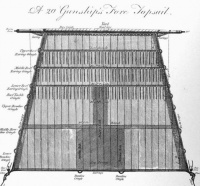

Introduction

Sails are indispensable for sailing ship. I only accept plastic sail substitutes in kits as a template for real canvas sails. Since many find it difficult to make sails, I offer canvas sails of excellent quality sewn on a CNC sewing machine. In the production process, I try to pay attention to all the technical details of how the sails were sewn to match the historical reality. Orders can be placed including patination or with printing. It is also possible to buy the canvas separately.

Canvas, cloth, stitching – batiste – 100% cotton, grammage – 88 gms. Stitching is also by thread from 100% cotton or colored synthetic threads.

Before you buy sails

Scale - Before you buy the sails, you have to take into account for which model, in what scale the sails will be. For large scales from 1:xx to 1:150 you can buy sails sewn with all the details such as curved edges, reefing strips, side and corner or additional reinforcement, sail lining. For scales 1:160 and above I recommend only sails sewn on canvas, which you can further adjust.

Set up sails on ship – It is advisable to think in advance whether you will put all sails on the model or only some of them. Here you can leave out the studding or staysails. And also whether and which sails will be furled or only partially furled. Depending on this, I recommend buying standard sails or shortened and reversely bevelled sails to imitate furled sails so that they don't look unnaturally bulky on the yard.

Patination and printing – The sails were mostly stained dirty beige or grey by use and mainly by impregnation. Some of the sails were made of coloured fabrics, mainly for galleys and xebecs. And some sails had coats of arms, crosses and other symbols painted on them. This should also be taken into account when ordering.

If you buy printed sails, acetone-based varnishes cannot be used for impregnation, as this would damage the print!

Preparation of sails

Sail type by boat - The sails were divided by their appearance and construction into main groups according to the region of origin of the ship, continental and English.

An example of the appearance of Continental and French sails is the sails of L' Ambiteux. Descriptions of French sails can also be found, for example, in specialist literature, in The Seventy-Four Gun Ship vol.3

A detailed description of English sails can be found on the Historic Naval Shipa Associatio website, specifically in The Elements and Practice of Rigging and Seamanship/ Sail making. And a specific example of such sails are those of HMS Victory.

Before we place the sails directly on the model, we need to do the following steps:

Painting of sails:

The sails of some, especially American ships, such as the USS Constitution, their schooners and brigs, had sails made of cotton cloth, which bleached in the sun with use in salt air. That's why I recommend leaving these sails white. Most of the other sails were beige or grey. You can achieve this by patinating in a strong decoction of black tea, coffee, spirit stain or fabric paint. The longer the fabric is in the solution, the darker it becomes. That is why I am adding a piece of fabric to the sail set, so that you have the opportunity to do a test.

It didn't pay to stain the sails in a broth of onion skins. The color was kind of an old yellow afterwards, and it got even more yellow when I reinforced them with Sidolux to hold their shape. But it's possible I just didn't have the onion skins dried properly, or the young onions....

Iron the dried sails, cut off excess threads.

Finishing sails – Bolt rope and Reef rope, Bowlines:

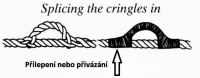

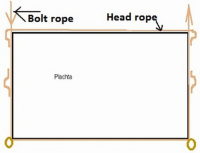

Accessories of sails - The circumference of the sails was strengthened by a so called bolt rope. This rope was sewn to the rear edge of the sail. It was of two pieces, the top part "Head rope" and the "Bolt rope". The corners of the rope formed eyelets - see fig. Over the top eyelets "Earings", the sail was attached to the yard, while the lower eyelets were used to attach the tension and cassation ropes, reins and halyards. Around the perimeter of the Bolt rope, eyelets were attached for lashing additional ropes handling the sail. Reef points were attached in the Reef Band to undercut - reducing the size of the sail area.

Bolt rope - The diameter of the Bolt rope was, like everything else on the boat, determined by the ratio of the thickness of the ropes to the respective Shrouds. The lower sails (Course) had Bolt ropes 3/4 the diameter of the lower shrouds, the top sails had Bolt ropes of the same diameter as the shrouds. The other sails had appropriately thinner ropes.

Before attaching the rope itself to the sail, you could attach eyelets (cringles) to the Bolt rope on the large scales (1:xx to about 1:100), where the other control ropes were tied in. Stretch the rope along the sail, marking the attachment points for the eyelets, leaving enough overhang at the ends. Remember that Bolt rope is one piece along the sides and bottom, so I recommend gluing the eyelets to the rope and the rope itself to the sail on each side. Make the eyelets from the same rope, and attach it to the Bolt rope itself either by gluing it with gel second glue, or wrap the ends of the eyelets with thin thread as shown in the following picture.

Attach of the bolt rope – Before you start attaching the rope to the sail, find out where the sail belongs, how it is turned and where the top and bottom and the front and back are. Each sail has a wider curve on the side attaching it to the jib or mast, but be careful not to reinforce it with more canvas. You can sew the rope to the sail or glue it with flexible gel second glue - usually glue is used for this connection. To make the job easier, clamp the sail in long, self-tightening tweezers, for example, or between two spars so that only part of the edge of the sail protrudes over the edge. Apply the gel superglue, attach the prepared rope correctly to the edge of the sail and press lightly against the edge of the sail. For easier and faster drying, it is advisable to slightly dampen the rope as the moisture present speeds up the drying of the second glue. Once dry, make a loop on the bottom corner of the sail, preferably using a log (e.g. skewer) so that the loop is the same on both sides. Wrap the eyelets at the corners with thread (see the picture below for options throughout the story). Do this on all sides of the sail. Work in this way on all sides of the sail.

Reef points - Reefing ropes are ropes that were used to tie the sail to the yard when it was necessary to reduce its area. They were threaded through the reefing belt to reinforce the sail. There was a knot at the sail so that the rope could not move to one side or the other. You can make reef points out of thinner rope. To make the ropes the same length, trim them to the same length after threading them through the sail.

Bowlines – Simply put, they were used to shape the side edge of the sail so that the sail would not catch the wind from the front. Again, the implementation varied according to the time and place of the ship's construction. Bowlines should be attached to the sail at this stage, or when the sail is on the yard, as it is much harder to do later on the model.

Different types of Bowlines:

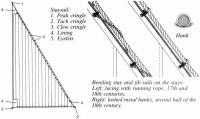

Attach of the sails to the yard and stay:

Yard sails - Attach the sail to the yard only when the other equipment (blocks or footropes) is attached to it. Again, pay attention to where the top and bottom, front and back of the sail are. The attachment of the sail to the yard has evolved over time, and is aptly illustrated in the attached picture.

Stay and Jib sails - The sails were hung on the stays by wrapping rope around them, later they were attached to the stay by clamps so called "Hanks", which were sewn to the sail and strung on the stay.

Shaping of sail:

As a final step before the yard and sail are attached to the mast, the sail must be given its shape. There are various ways to shape the sail. Someone shapes the sail according to plastic templates, someone according to a bottle of the appropriate diameter. I attach the finished sail to the frame, the corners of the sail are attached in the same way as if it were attached to the boat, see picture.

First, iron the sheets thoroughly so that they are straight and free of creases and scratches. You can paint the sails with your choice of reinforcing varnish (ideally a matt varnish, I use matt acrylic Sidolux), or a very diluted Hercules. You can also use a different reinforcing varnish, depending on how everyone has tried it. Maybe a classic liquid starch for canvas. And for small sails, hair spray is fine. Choose the dilution of the impregnating solution so that it soaks into the sail well, does not form a visible layer when dry, but is nicely soaked in, and the sail is stiff and holds its shape well. Blowing into the sail with a hairdryer will dry the impregnation and get the optimum shape. At this point (while it is drying) you can arrange the various folds in the corners or folds if you want them on the sail. It is especially important to do this when you are making a folded or undercut sail. With a folded sail, roll it all up and tie it straight to the yard.

If you buy sails with a print, you can not use to impregnate paint of acetone-based, as it will damage the print!

Attach the sail to the boat, on which you have already prepared the rigging. My preferred procedure is to have all the fixed rigging installed and the running rigging secured to the mooring point on the boat, including the decorative coils of rope, before starting to fit the yard.

In the picture below you can see the sails properly prepared for installation on the model. The next pictures show examples of finished sails mounted on the model.

I hope these lines will help you in creating your models. Please feel free to contact me with any questions. I will be glad to help you if I can.

I wish you many beautiful models with great rigging!

Source of images:

book - Historic Ship Models from Wolfram zu Mondfeld web - http://www.hnsa.org/

fig. 1

fig. 1 fig. 2

fig. 2 fig. 3

fig. 3 fig. 4

fig. 4 fig. 5

fig. 5 fig. 6

fig. 6 fig. 7

fig. 7

fig. 10

fig. 10